Pumps

Heat exchanger pumps are primarily used to pump product into the heat exchanger cylinders. Exchanger pumps have very tight tolerances. Overtime, as product is pumped through the unit, gears, gaskets and covers may become worn causing the pump to lose pressure or its ability to move product.

Utilizing US and metric tolerances are no problem for our CNC and manual machines

Utilizing US and metric tolerances are no problem for our CNC and manual machines

Our Repair Process

Each pump body begins with an extensive inspection against factory specifications. If repairs are necessary, the inner diameter of the housing will be stripped, welded, machined, ground, re-chromed and polished to manufacturer’s specifications (if applicable). All parts that are damaged beyond repair will be replaced by Litre. All pumps are tested on the appropriate fixture; activated, re-inspected, cleaned, polished, packaged and shipped.

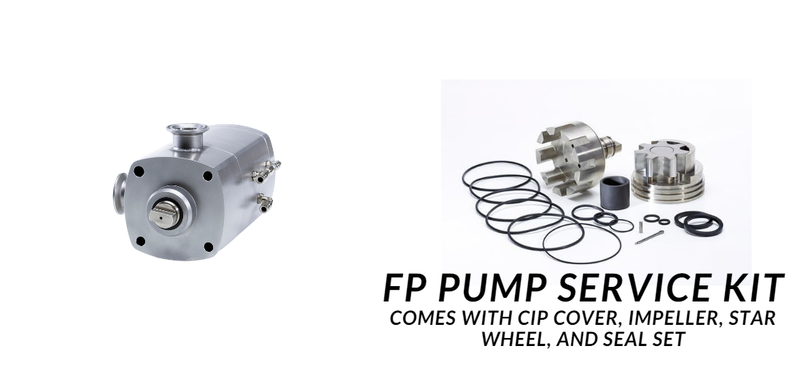

Litre Service, Inc. not only repairs, but supplies many OEM equivalent pumps and pump parts at a fraction of the cost of buying new. All parts furnished to customers undergo vigorous and extensive quality tests prior to delivery.

Litre Service, Inc. not only repairs, but supplies many OEM equivalent pumps and pump parts at a fraction of the cost of buying new. All parts furnished to customers undergo vigorous and extensive quality tests prior to delivery.