Freezer Cylinders, Barrels, Votators & Tubes

|

Scraped Surface Heat Exchangers consist of a jacketed cylinder with a rotating dasher holding rows of scraper blades. During the manufacturing process, fluid product is pumped through the inner diameter of the cylinder while the heating or cooling medium is circulated between the outer diameter of the tube and the jacket. The thermal medium can be steam, water or a refrigerant such as ammonia or freon.

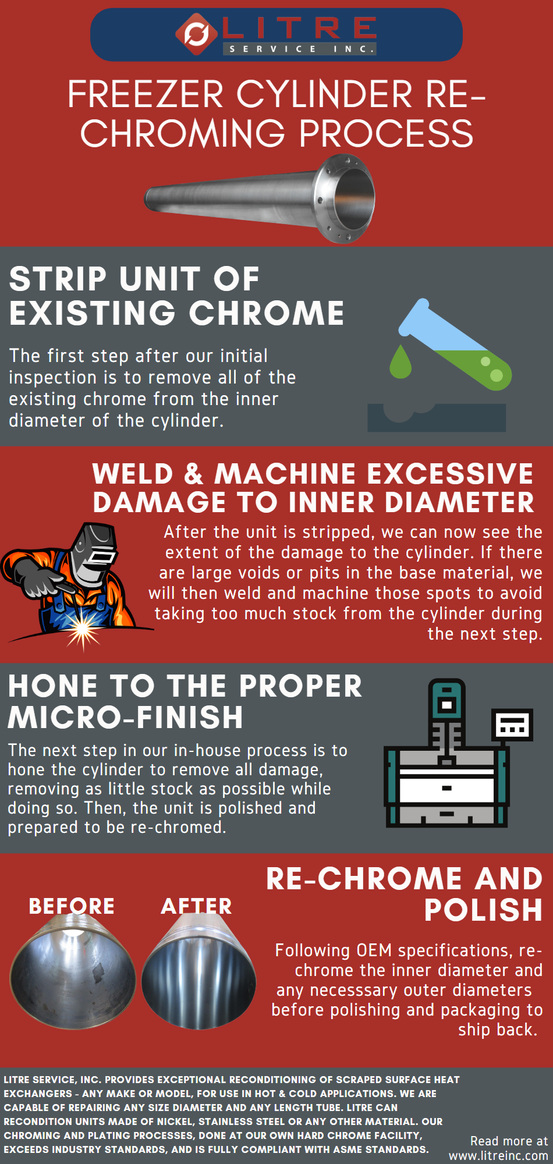

Scraped Surface Heat Exchangers create the ability to heat and cool fluids composed of tiny particulates--some only a few millimeters in diameter. Scraped Surface Heat Exchangers can also heat and cool highly viscous products, such as peanut butter, shortening, caulk, and mascara. Our chroming and plating processes, done at our own hard chrome facility, exceeds industry standards, and are fully compliant with ASME Standards. We are fully tooled to recondition units back to factory-performing-standards. |

|