Ingredient Feeders & Fruit Feeders

Fruit Feeders are used to enhance frozen products by introducing fruit, nuts, candy, and other inclusions at the time of production.

Our Repair Process

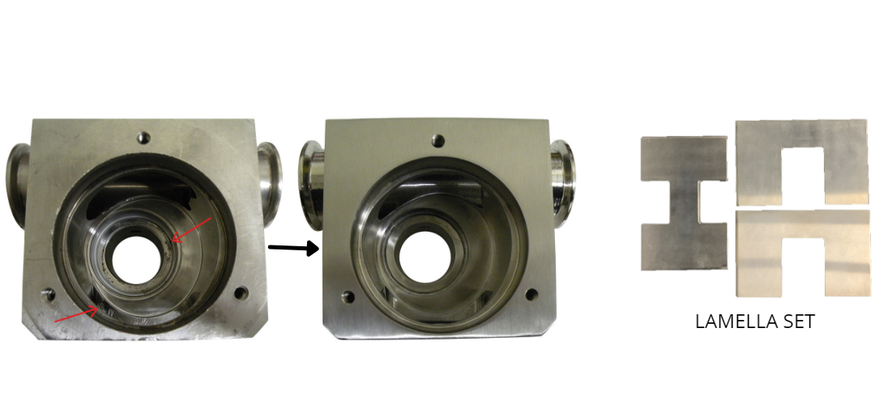

Each unit begins with a thorough inspection of all wear diameters. First, impeller bearing IDs and wear surfaces are welded, machined, hard-chromed, and ground back to manufacturer's specification. The surfaces are then smoothed of all gouges and all threaded studs are repaired or replaced as needed. The outside of the housing is cleaned and polished; and if necessary, the pressure plate is stripped of existing chrome, repaired, and re-chromed per manufacturer's specification.

Litre Service also specializes in manufacturing new, OEM-equivalent wear parts such as impellers, rotors, lamellas, and more. Take a look at our ingredient feeder shop to see more.

Litre Service also specializes in manufacturing new, OEM-equivalent wear parts such as impellers, rotors, lamellas, and more. Take a look at our ingredient feeder shop to see more.