|

0 Comments

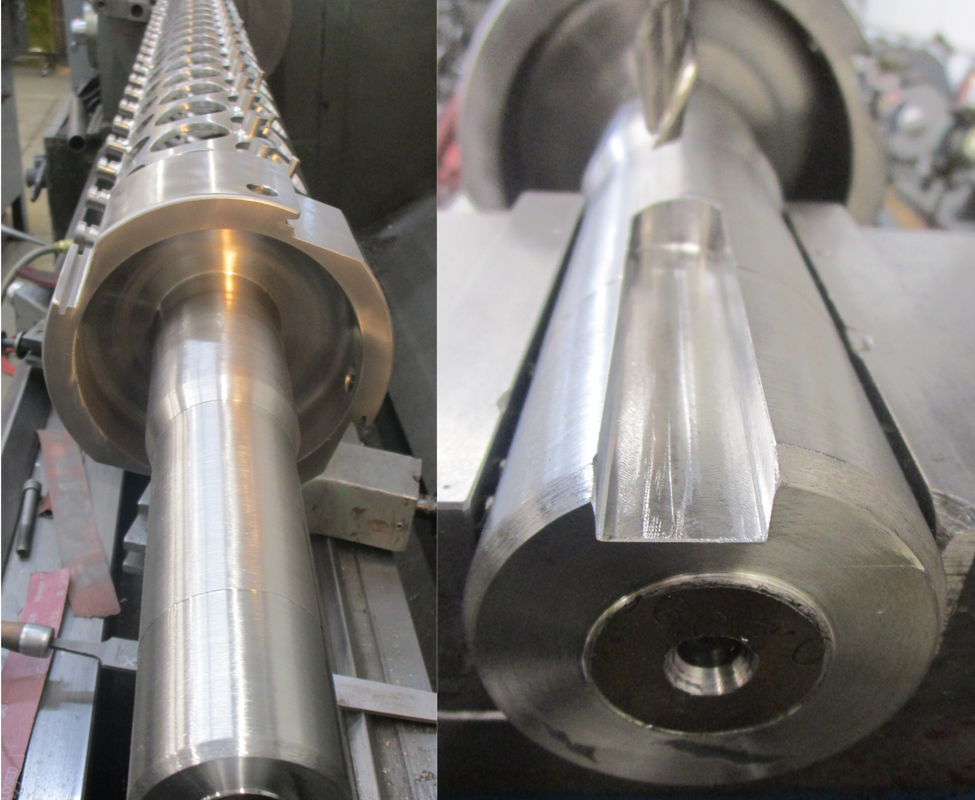

Nine times out of ten, when refurbishing a dasher, we need to cut and replace the spline end. This dasher has a brand new, OEM-equivalent, 2.153" diameter spline with 26 teeth. Reach out to Litre today for dasher and mutator work.

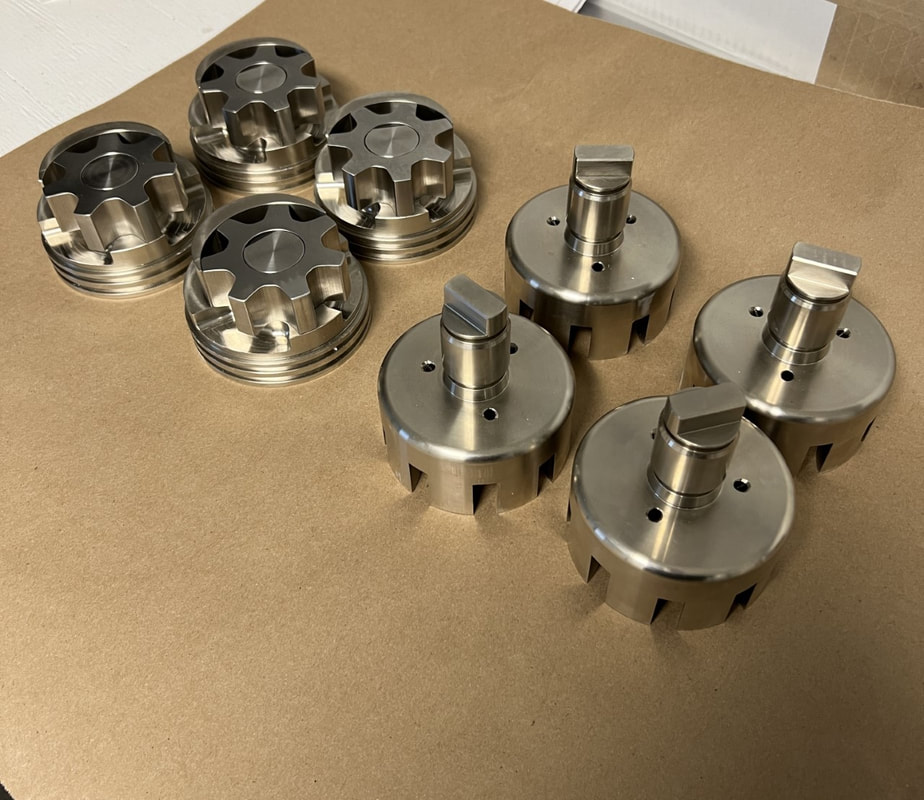

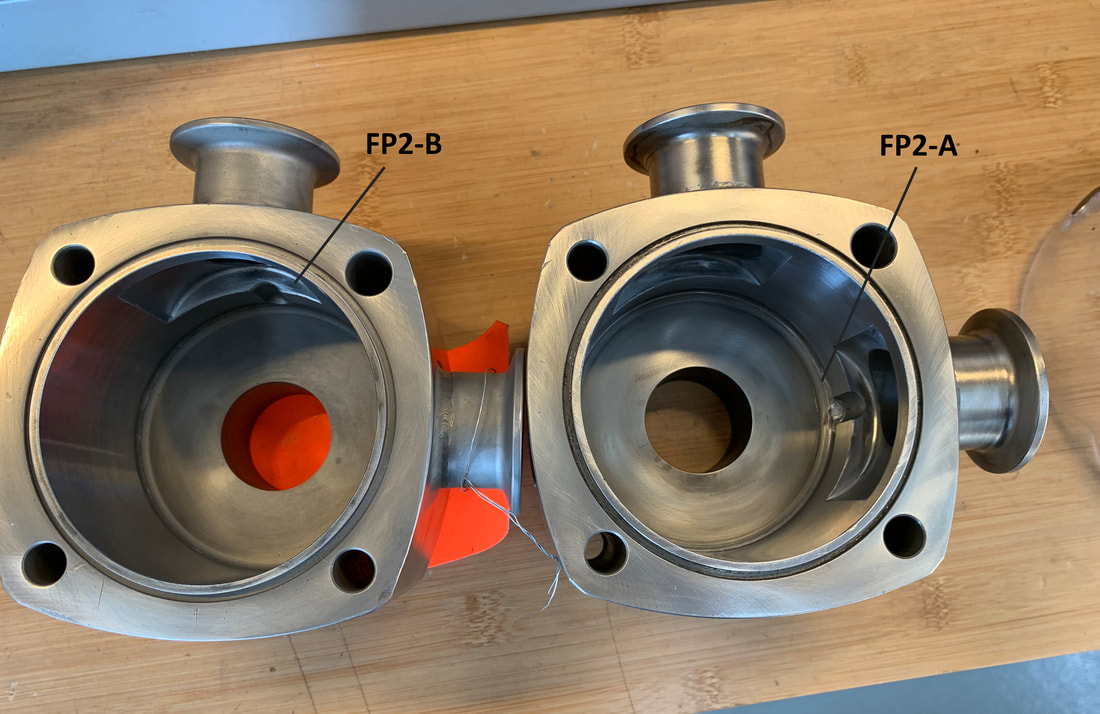

Take a look at our pump parts store to see these FP2 service kits and more.

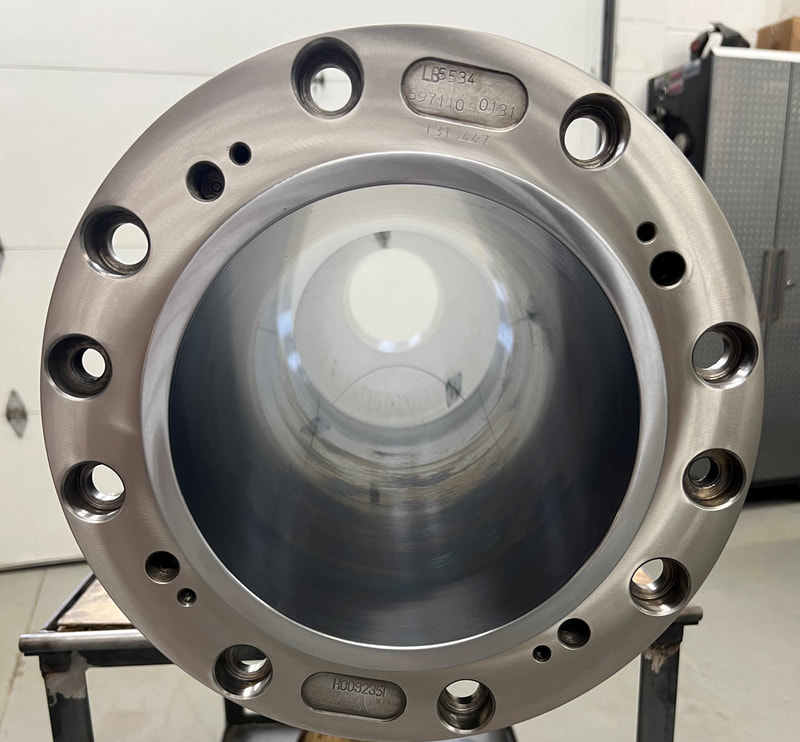

This KF2000 freezer cylinder was stripped of its existing chrome, honed, re-chromed, polished, and returned to the customer all in less than 10 working days! Reach out today to learn more.

Reach out today for service kits, scraper blades, seals, and other various processing equipment and parts. Simply go to our contact page and give us a part number and description and we will get to work on a quote with the best pricing and lead time that you can find.

We are always open to purchasing equipment in exchange for an in-house credit, good towards any future repair work. Contact us today!

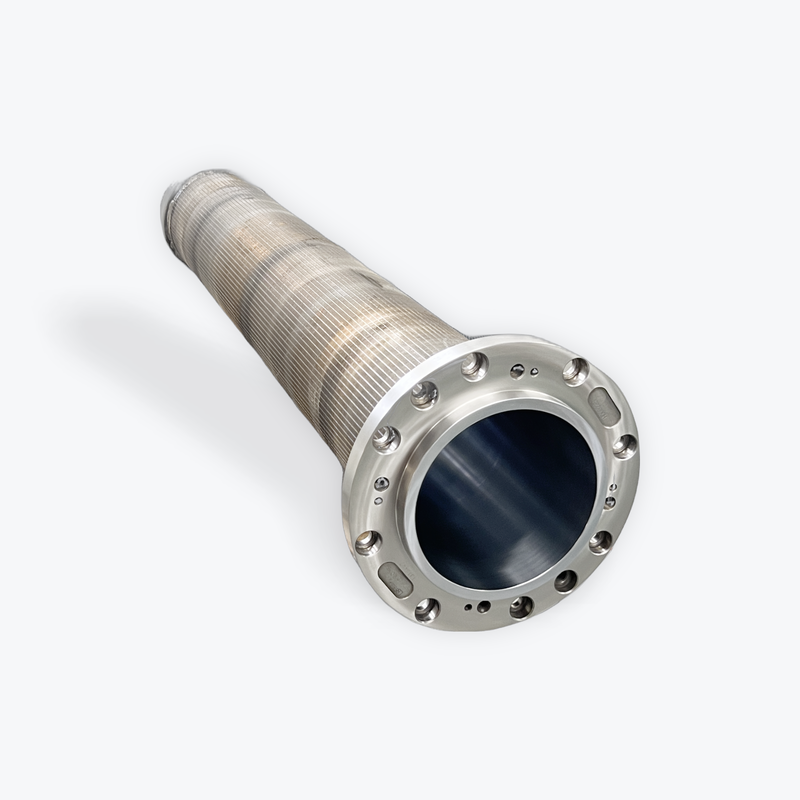

Litre Service is fully equipped to manufacture OEM-equivalent freezer cylinders from raw material. Reach out today for a quote.

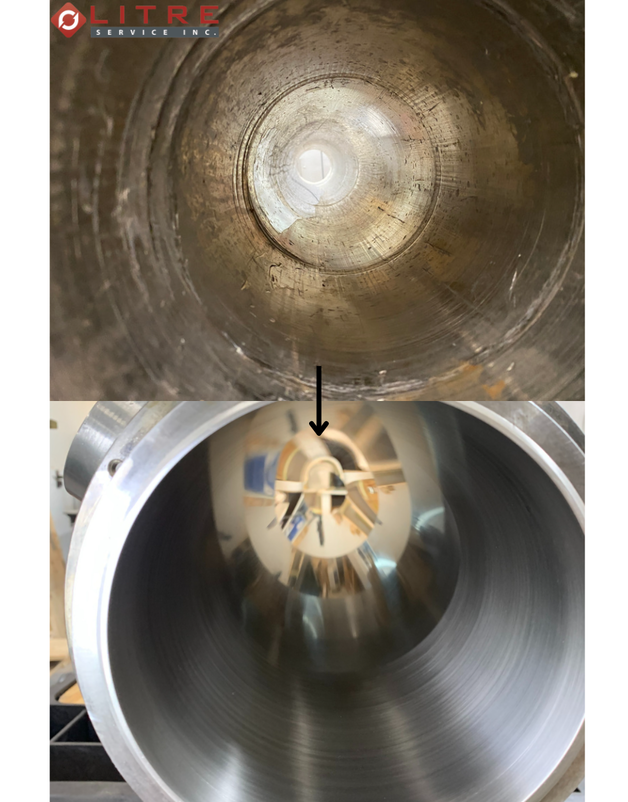

This can cause your scraper blades to come loose and in turn, damage your cylinder. Blade pin reconditioning is one of our steps for a standard dasher repair. Send it to Litre!

Litre Service has full capabilities to refurbish even severely damaged equipment, like this 6" x 72" nickel cylinder.

The wear diameters were welded and machined to size, the shafts were straightened, and the gears were deburred and polished. All done in house here at Litre, for a fraction of the OEM's price.

Cutting and replacing the drive spline with new is a part of our standard dasher / mutator / blade shaft repair process.

Our customer reached out to us after seeing their quote from the OEM and were able to get their parts less expensive and faster from us. We are the complete solution for your processing needs.

Litre Service offers keyway cutting, spline cutting, and full dasher refurbishment. We also carry an inventory of refurbished dashers with brand new drive shafts.

Works for all Hoyer FP pump models, simply adjust your pump housing so that the ports are facing the direction shown in the photo below and look for the position of the indent. This dictates your product flow.

|